Quilting machine gradually computer control course

Release Date: 2012/9/19 15:20:24 Total access[5118]TimesIn the nineteen seventies start computer control technology gradually infiltrated by mechanical control is the basic control mode of the quilting machine products.Review of nearly 40 years of computer control technology in quilting product application development process, it is mainly through the following aspects: gradually infiltrated by mechanical control is the basic control characteristics of the quilting machine products.

Over the past 100 years, the human in the use of mechanical control mode to control the quilting machine coordinate synchronous movement during development, are constantly looking for the best mechanical control mode to achieve the best effect of stitch.When sewing thick material to adjust, when quilting thinner materials to adjust, the thickness of the material is not the same, quilting machine each needle bar, the hook line, thread, feeding four agencies in spindle assembly output signal parts structure and position are not the same.This is because the quilting machine motion control signal is solidified in a quilting machine control parts of the structure and assembly process, not the editor.Mechanical control mode stability and anti-interference than computer control mode, so the machine working stability is better.This is with mechanical control is the basic control mode of the quilting machine product technology feature.

Over the past 100 years, the traditional quilting products on-line trace formation quilted objective process, the needle bar, the hook line, thread, feeding four major mechanisms for coordinated operation is mainly adopts the mechanical control mode.Whether it is home machine, sewing machine and sewing machine, stretch sewing machine, they realize the stitch formation process in the needle bar, the hook line, thread, feeding four major agencies to coordinate the operation control signal, are made of quilting machine making and control.In a stitch forming cycle process, the needle bar, the hook line, thread, the feeding of the four major agencies movement coordination, is to ensure that the stitch forming quality of key.Such as sewing machine on the needle bar mechanism motion signals are first by the assembly on the spindle from the needle bar crank position; the thread-taking-up mechanism motion signal is first by the assembly on the spindle from the needle bar crank position; feeding mechanism motion signals are first by the assembly on the spindle feed the eccentric wheel and the eccentric wheel is a tooth lifting position; thread hooking mechanism motion signals are first by the assembly on the shaft bevel gear or belt wheel position issued.Modern control theory language, quilting machine spindle is the main motion quilting machine control box.It controls the needle bar, the hook line, thread, the feeding of the four major agencies movement coordination, to achieve stable formation of stitch quilting purposes, but all the control signal is solidified in the quilting machine control parts of the structure and assembly process, not the editor.Therefore, adjusting the needle bar, the hook line, thread, feeding four agencies in the spindle output signal component position,

To coordinate the needle bar, the hook line, thread, the feeding of the four major agencies of coordination, synchronization.This coordination, synchronization is composed of quilting machine parts product quality and assembly process to guarantee the.

News source: HengYeJiXie

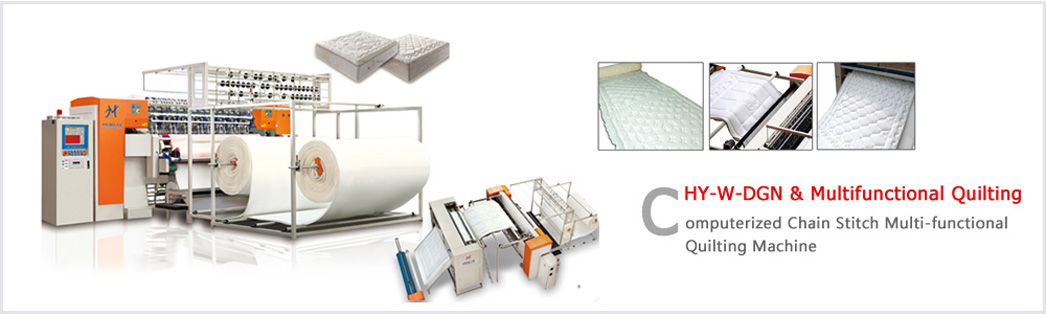

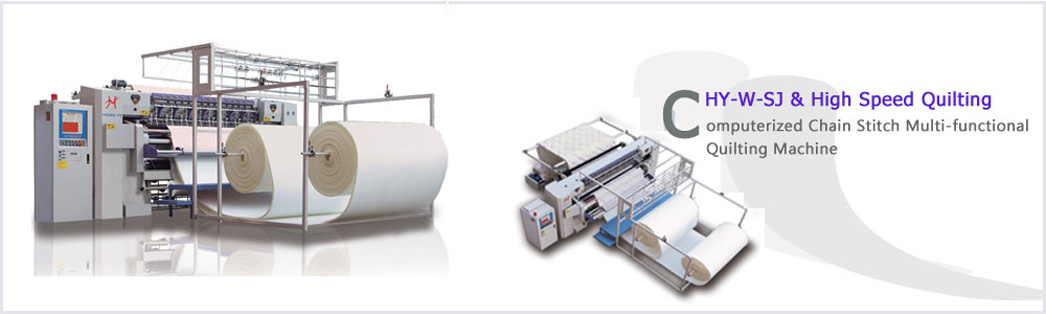

- Computerized Chain Stitch Multi-functional Quilting Machine

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-DGN )

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-SJ)

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-JH )

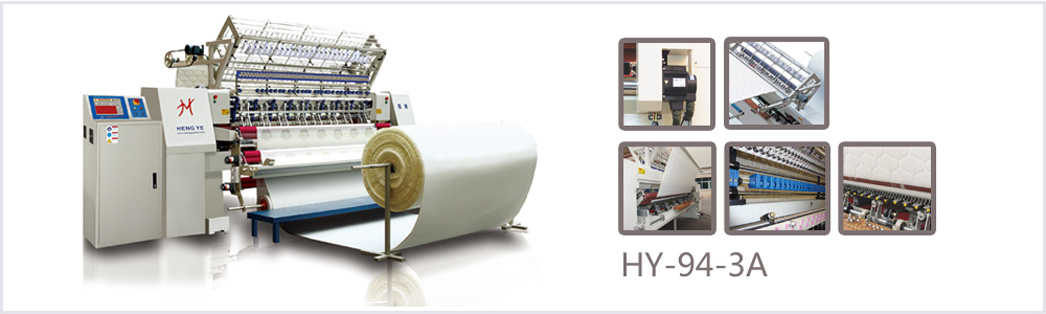

- Computerized Lock Stitch Multi-needle Quilting Machine

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-64-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-94-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-64-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-94-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-128-3A)

- Computerized Quilting and Embroidery Machine

- Computerized Quilting and Embroidery Machine【New】(Model:HY-HX02-128)

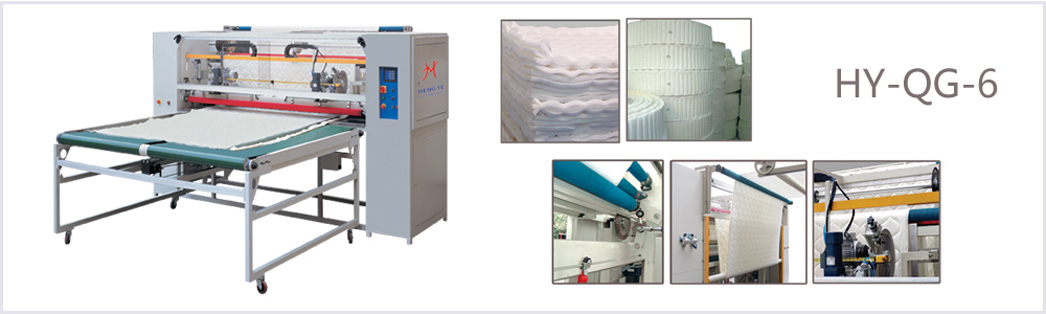

- Computerized Panel Cutter Machine

- Computerized Panel Cutter Machine【New】(Model:HY-QG-6)

- Computerized Panel Cutter Machine(Widen)【New】(Model:HY-QG-6L)

- Computerized Panel Cutter Machine(Model:HY-QG-3)

- Computerized Panel Cutter Machine(Model:HY-QG-2)

- Quilting Machine Accessories

- Bobbin Winder Machine(Model:)

- Knife Grinding Machine(Sharpen Machine)(Model:HY-MD-1)

- Material Roller Machine(Model:HY-JB-1)

- Material Roller Machine(Model:HY-JB-2)

中文简体

中文简体 English

English Español

Español العربية

العربية  Français

Français