Domestic Quilting Control System Software

Release Date: 2010/7/3 17:27:16 Total access[4732]TimesThe computer control system of quilting for saddle framework and key technology of linkage with the needle roller control technology, computer quilting machines using CPU parallel processing technology, quilting machines working for data processing and transmission, has greatly improved the old traditional way of mechanical work inverter to better solve the saddle frame control, Laura control and spindle control key technology, quilting realized quilting products production process automation, with strong fault-tolerant function, break the automatic stop function, automatic detection and overheating protection measures to protect and system fault diagnosis, but also has the ability to set parameters, management and more than 40 kinds of function, meet many quilting processing enterprise in various more shuttle quilting machines, quilting machines, needle shuttleless more hook quilting machines and single head hook quilting machines are the shape and the old machine is fit and quilting processing of urgent need.

Quilting machine control system overall technical design of high starting point, good compatibility and strong anti-jamming capability, according to the international design practices and computer quilting machines for optimization design of specific requirements. Its technical characteristics are mainly embodied in the following aspects:

1), in the saddle and Laura system control technology in the saddle, according to the actual load or rollers, ball screw and belt transmission principle, the suture needle sewing speed and motion and sewing needles embossed with many parameters, the phase of rational choice saddle or roller drive motor, precise saddle or Laura acceleration and time, optimize the design of roller drive instructions or saddle, ensure control curve quilting quality and quilting yield, saddle or roller system control technology, the overall design level with stepper motor servo motor drive instead of the saddle, so as to improve the saddle and Laura overall system performance.

2), in the spindle system control technology, according to the actual load, belt transmission shaft and speccial principle, the suture sewing stitching etc., reasonable choice of parameters of spindle drive motor spindle acceleration, the calculation and optimization design of spindle drive speed control curve, ensure instructions quilting quality and quilting yield, spindle system design, technology development level in converter with vision.

3), in the whole system hardware and structure, function and performance index system, optimize the design of the system, system diagram carefully resistance performance of the system design, industrial environment and working stability design and system security design technology and strict control and the amount by components design method, reasonable choice of computer chips and various components and integrated circuit chips, to the best prices and high reliability for realizing functional units. Adopt shielding, thermal design and correct wiring way realization environmental electromagnetic compatibility.

4), in the control system software, software defect, the inherent in the complexity of the environment, the error on the design of the software also adopted a series of measures, and in the process of implementing quilting, various actuators, eliminate monitoring interference factors such as the system, improve the misoperation of reliable performance.

News source: HengYeJiXie

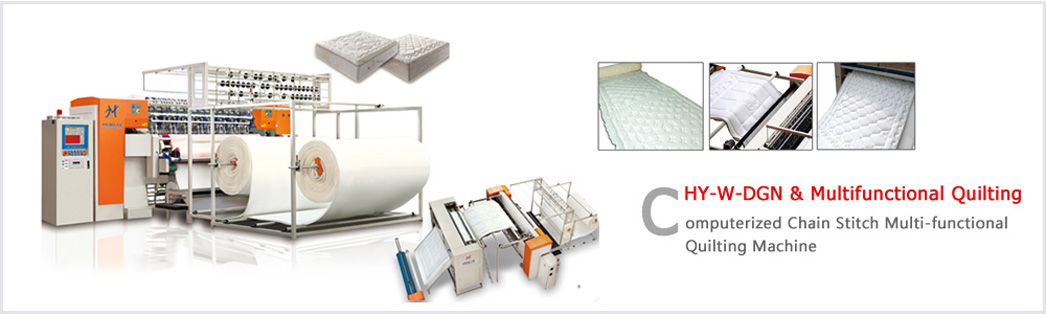

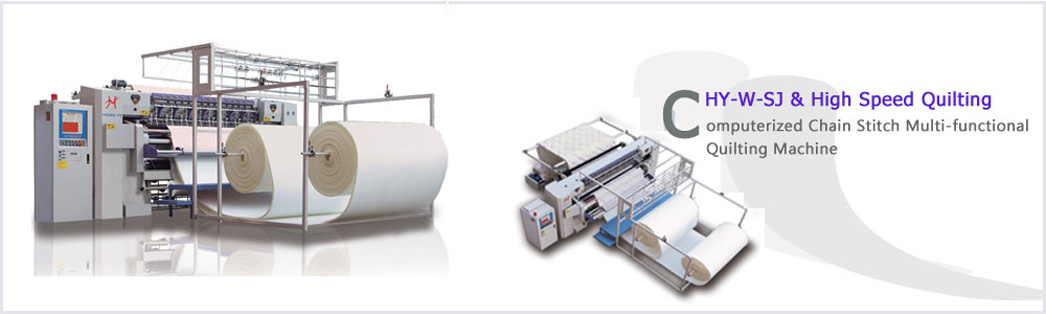

- Computerized Chain Stitch Multi-functional Quilting Machine

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-DGN )

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-SJ)

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-JH )

- Computerized Lock Stitch Multi-needle Quilting Machine

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-64-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-94-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-64-3A)

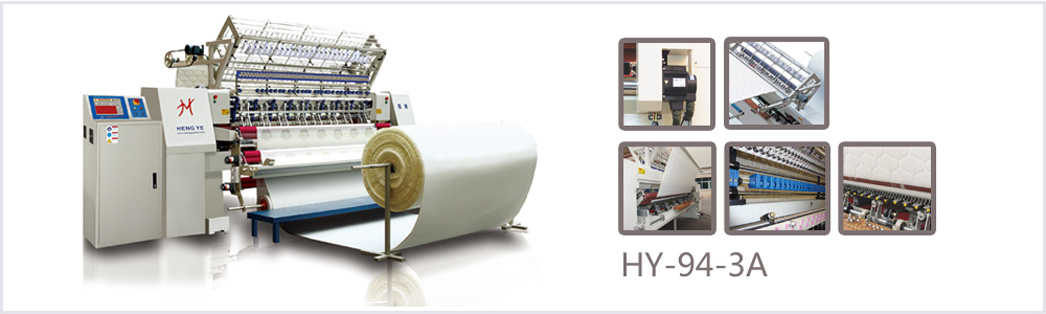

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-94-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-128-3A)

- Computerized Quilting and Embroidery Machine

- Computerized Quilting and Embroidery Machine【New】(Model:HY-HX02-128)

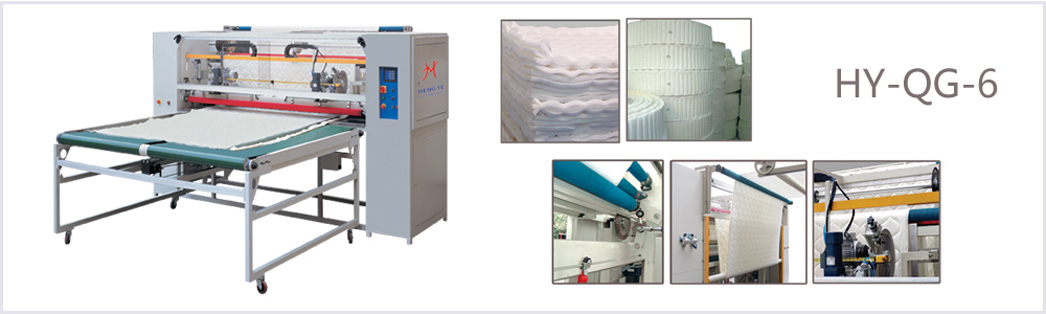

- Computerized Panel Cutter Machine

- Computerized Panel Cutter Machine【New】(Model:HY-QG-6)

- Computerized Panel Cutter Machine(Widen)【New】(Model:HY-QG-6L)

- Computerized Panel Cutter Machine(Model:HY-QG-3)

- Computerized Panel Cutter Machine(Model:HY-QG-2)

- Quilting Machine Accessories

- Bobbin Winder Machine(Model:)

- Knife Grinding Machine(Sharpen Machine)(Model:HY-MD-1)

- Material Roller Machine(Model:HY-JB-1)

- Material Roller Machine(Model:HY-JB-2)

中文简体

中文简体 English

English Español

Español العربية

العربية  Français

Français