Computerized quilting machine common fault processing method

Release Date: 2012/8/15 17:37:35 Total access[3983]TimesAs for now

The 1 voltage instability

Exclusion way: stable voltage computer screen does not show

2 error

3 display a problem 1 unstable voltage 2 rail is not flexible 3 grounding failure

Restart after shutdown

Replacement or repair of stable voltage clean track replacetightening terminal pressing screw plug inserted immediately

Machine quilting machine didn"t work out

Wire terminal connector loosening loosening or

1 Selection of machine needle improper or needle bent

2 needle method is improper

Exchange, adjustment check, checking, adjustment of needle exchange machine

The 3 rotary shuttle loosening, improper matching

4 foot loose displacement

1 needle bent or machine - choosing improper stitch

2 needle method is improper

3 the needle and hook with improper

Careful adjustment

The 1 wire error

2 line cross section line

too tight

3 line too poor in quality

Adjusted replacement suture, construction using 60 three shares of light

4 needle rough

5 wire system is not smooth at

6 the needle and hook parts improper stepping motor phase

Replacement correction inspection, sand grinding smooth carefully adjusted according to F5 enters the system test respectively measuring X, Y axis, find out the corresponding drive, metal tube or 260 synchronous belt teeth bad ① replace photoelectric sensor, replacement, make bad sensor a short line, to install X axis Y axis, the abnormal sound, at slow speeds, sewing, air travel time size does not reach the designated position (shorter)

Reasons: ① drive power itself is the cause of the inner metal tube caused by the breakage of

Normal sewing, X, Y shaft cannot normally (walk slowly) in suspension, the needle bar does not return to the F5 into system test needle, needle position without change of 0,1

① photoelectric sensor damaged II head on the loose belts

The head of each bearing inspection, adjustment screw so that the main shaft concentrically, nylon gear tooth replacement if the tensioning belt or spindle belt loosening

Fault phenomenon

A machine after the suspension head still slow rotation does not stop

Equipment test

Troubleshooting method

Remarks

F5 B test needle sewing frame after cannot enter such as no 0 and 1 reverse a replace the corresponding sensor, the sensor and the light within the box joint system, the power off of B check computer host to the sensing piece wheel gap on as 1 opposite 0 and Dan head still slow rotation stop after the multimeter for measuring C sewing after the end of head still slow rotation does not stop

The fault phenomenon: when sewing frame and a stepper motor having jitter 13 empty or empty back into a frame and the stepping motor "jitter 0 to wear line during the frame and a stepper motor having jitter 0 work falling needle in physical size 6 sewing frame and step motor or a direction fixed device test 75 test 4 directions: a framework and a stepping motor jitter or abnormal sound and power with a multimeter" synchronous belt is sliding tooth or offset "fixed chain clip whether there is loose

Troubleshooting method

& replacement of corresponding drive X or diachronic examination drives stepper motor and power supply line between whether open or short tender check stepper motor air plug is a good contact note

About "for X direction, up and down the Y direction for special attention: the drive of high risk of a professional must open detection.

News source: HengYeJiXie

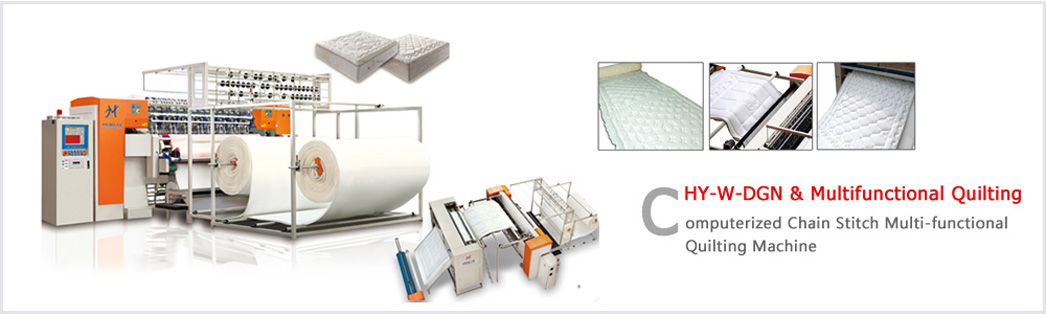

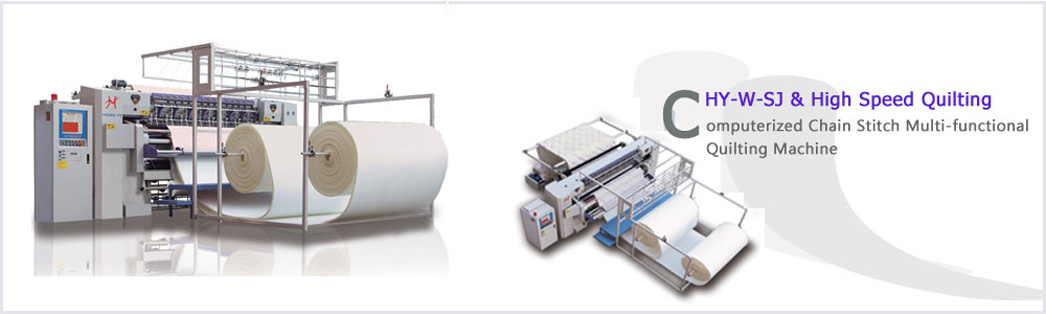

- Computerized Chain Stitch Multi-functional Quilting Machine

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-DGN )

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-SJ)

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-JH )

- Computerized Lock Stitch Multi-needle Quilting Machine

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-64-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-94-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-64-3A)

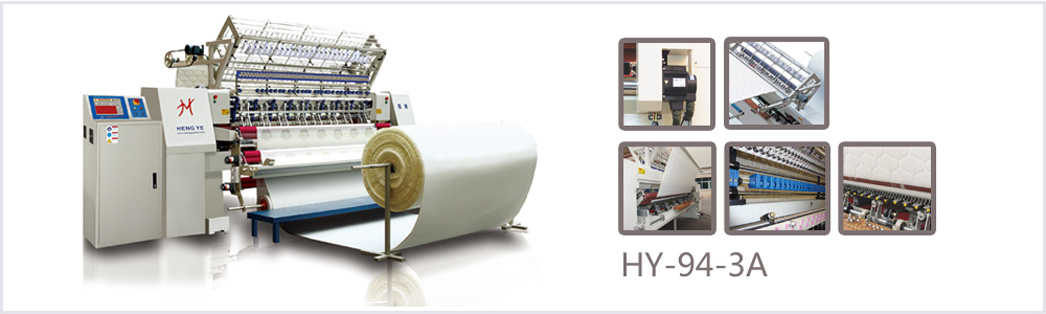

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-94-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-128-3A)

- Computerized Quilting and Embroidery Machine

- Computerized Quilting and Embroidery Machine【New】(Model:HY-HX02-128)

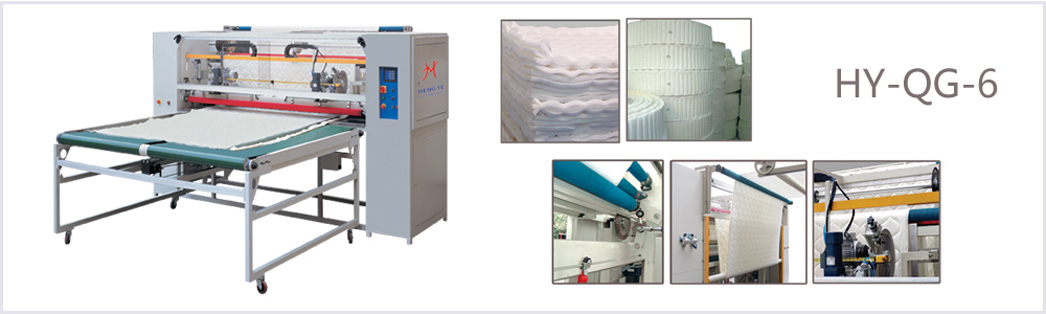

- Computerized Panel Cutter Machine

- Computerized Panel Cutter Machine【New】(Model:HY-QG-6)

- Computerized Panel Cutter Machine(Widen)【New】(Model:HY-QG-6L)

- Computerized Panel Cutter Machine(Model:HY-QG-3)

- Computerized Panel Cutter Machine(Model:HY-QG-2)

- Quilting Machine Accessories

- Bobbin Winder Machine(Model:)

- Knife Grinding Machine(Sharpen Machine)(Model:HY-MD-1)

- Material Roller Machine(Model:HY-JB-1)

- Material Roller Machine(Model:HY-JB-2)

中文简体

中文简体 English

English Español

Español العربية

العربية  Français

Français